Because of leaving of Russian market by the foreign manufacturers, were introduced into serial production in the tight schedule the systems of disc ...

The construction on two bloc brake elements: symb. N863 for the new highway electric locomotives OOO “Ural locomotives” (Verchnyaya Pyshma) and symb. ...

Into series production went:

disk brake system symb. N852 for railway crane KG-1473 of manufacturing AO “KMZ 1 May”;

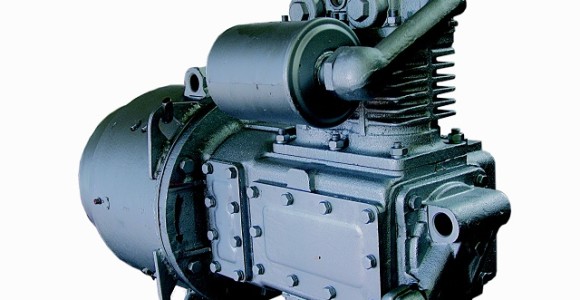

compressor aggregate AKB ...

AO “Transpnevmatika” received the Honorary standard of governor. The factory was included in national register of the leading Russia’s factories and ...

Acceptance testing of connector sleeves R60 those are intended for replacing of the sleeves “Knorr-Bremse” on the electric trains ES1 of ...

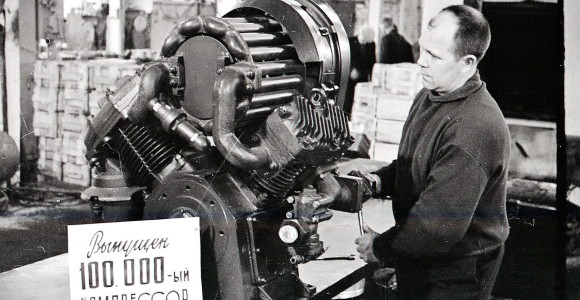

In that anniversary year of town and plant exceeded the factory’s performance targets the most adventurous expectations. During 10 years they have ...

In AO “Transpnevmatika” is begun the serialization of disc brakes for electric train “Lastochka”. The manufacturing of automatic regimes 265A-5-02 ...

Acceptance commission on the acceptance of the items for braking system of the electric train ES2G “Lastochka” is carried out:

brake bloc of ...

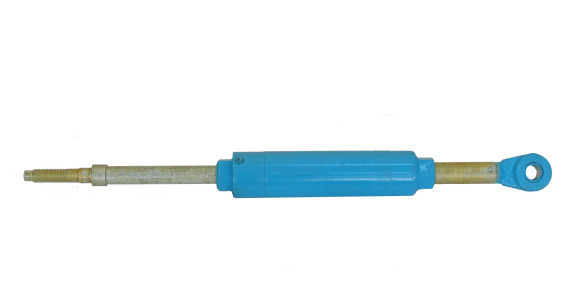

Serialization of the brake cylinders with integrated regulators of the rod output TTSR-10-85-1 and of the connector sleeves R36B-1 those are applied ...

At the factory is developed the manufacturing of automatic regimes 265A-5 and 265A-5-01 with the extended range of compressed air pressure adjustment ...

For solving of the question that is connected to the developing of the perspective production is created the scientific and technical center.

The ...

The settling of production of hydraulic units for the railway transport is begun.

The plant is reorganized in the open Joint-stock company for production of the compressor and the pneumatic units “Transpnevmatika”.

The different models of compressors, those replaced the compound-pumps are developed and introduced. Besides the compressors, the mass producing of ...

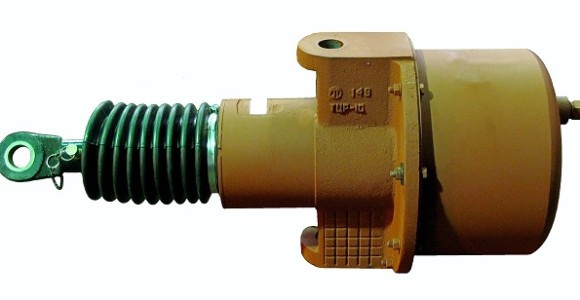

For the short term the first production batch of the brake cylinders with integrated regulator TTSR-10 is developed and manufactured.

The factory ...

The autocontroller N574B is batch productionized.

The compressor PK-35 for diesel locomotives and electric locomotives is developed.

The manufacturing of automodes of the brake riggings is assimilated.

The batchwork of the compressors for diesel locomotives, electric locomotives and trolley buses: EK-4, EK4A, EK7A is assimilated.

The output of tandem pumps for compressed air production is begun. At the same time is begun manufacturing of the connector sleeves and the ...

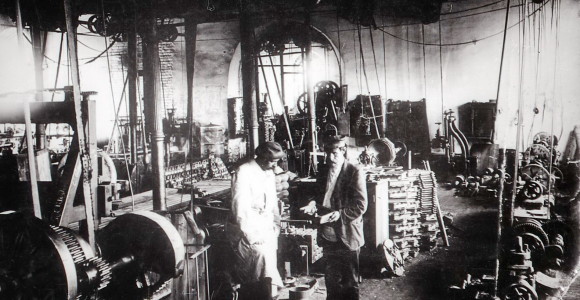

The technology and equipping is developed, the manufacturing of the compound pumps is begun. The merely metallurgical factory became a ...

The plant turns to producing of the products for front. The covers for the grenades and mines, the pots for food’s preparing were manufactured.

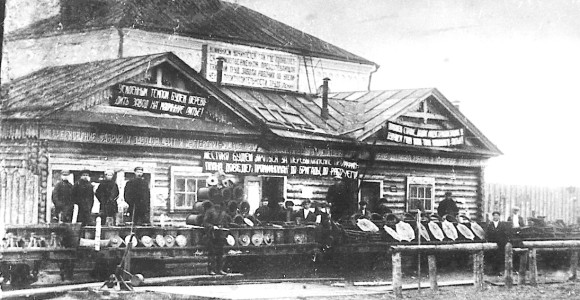

On 8th of September, 1922 was made a decision on the plenum of the Tashino party committee about the renaming of Tashino plant in Pervomaysk ...

On March, 1919 begins the plant to manufacture the production for railway transport: the bushes, brake blocks, buffer boxes, bearings, shoes’ blocks.

With the purpose of production’s expansion and formation of the additional cash means is created the first stock company “The society of Tashino ...

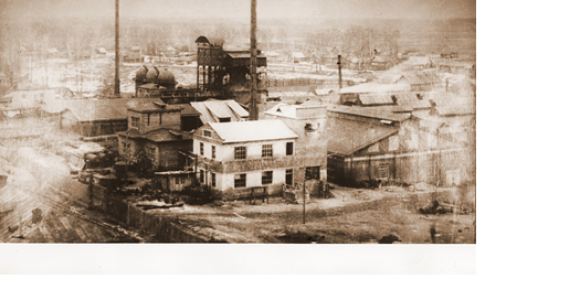

On 30th of July, 1853 was started up Tashino ironwork. This date became a reference point in the AO “Transpnevmatika”’s history. Although the plant ...